A 2-stroke Johnson outboard wiring diagram is an essential tool for understanding and troubleshooting electrical systems in these motors, ensuring safe and effective repairs and maintenance.

1.1 Overview of the Importance of Wiring Diagrams for Outboard Motors

Wiring diagrams are crucial for diagnosing and repairing electrical issues in 2-stroke Johnson outboards. They provide a clear visual representation of the motor’s electrical system, ensuring proper connections and safe troubleshooting. These diagrams are essential for maintaining efficiency, safety, and performance, covering everything from ignition systems to gauges. They are indispensable for both novice and experienced technicians, offering precise guidance for model-specific repairs and upgrades.

1.2 Brief History of Johnson Outboard Motors

Johnson Outboard Motors, established in the early 20th century, became a pioneer in marine engineering. Known for their reliable 2-stroke engines, Johnson introduced innovative designs like the first electric start model in 1965. Their commitment to performance and durability made them a leader in the outboard motor industry. In 2001, Johnson merged with Evinrude, continuing their legacy of producing high-quality motors for boating enthusiasts worldwide.

Key Components of a 2-Stroke Johnson Outboard Wiring Diagram

The wiring diagram includes the ignition system, trim and tilt mechanisms, and gauges, providing a clear guide to electrical connections and circuit pathways for proper motor function.

2.1 Battery and Ignition System

The battery and ignition system are fundamental to starting and operating the outboard motor. The wiring diagram details connections between the battery, ignition switch, and ignition coil. Proper voltage levels and clean connections ensure reliable spark generation for the spark plugs. The ignition system’s integrity is crucial for efficient combustion in the 2-stroke engine, with specific wire color codes aiding in circuit tracing and diagnostics. Regular inspection of these components prevents malfunctions and ensures smooth operation.

2.2 Trim and Tilt Mechanism Wiring

The trim and tilt mechanism relies on precise wiring to control the motor’s angle and depth adjustments. The wiring diagram illustrates the connections between the trim switch, tilt motor, and electrical relays. Proper wiring ensures smooth operation, while incorrect connections can lead to mechanical failure. Regular inspection of these wires and connections is essential for maintaining the motor’s performance and functionality during operation, as outlined in the manual.

2.3 Gauges and Instrumentation

Gauges such as tachometers, speedometers, and fuel indicators are crucial for monitoring the outboard motor’s performance. Their wiring, as shown in the diagram, connects sensors to the display units, ensuring accurate readings. Proper connections are vital for reliable operation and troubleshooting. Regular checks of gauge wiring help prevent errors and maintain optimal engine performance, as detailed in the manual for 2-stroke Johnson outboards.

Tools and Materials Needed for Wiring Repairs

Essential tools include a multimeter, wiring diagram PDF, wire strippers, and heat shrink tubing. These tools help diagnose and repair electrical issues efficiently and safely.

3.1 Multimeter for Electrical Troubleshooting

A multimeter is crucial for diagnosing electrical issues in 2-stroke Johnson outboards. It measures voltage, current, and resistance, helping identify short circuits or open connections. Use it to test battery voltage, ignition coil resistance, and wiring continuity. Ensure safety by using the correct range and avoiding direct short circuits. This tool is indispensable for precise and efficient troubleshooting of electrical systems.

3.2 Wiring Diagram PDF for Reference

A wiring diagram PDF for 2-stroke Johnson outboards is essential for understanding electrical systems and troubleshooting. It provides detailed schematics of components like ignition, trim, and gauge wiring. Referencing a PDF ensures accurate repairs and maintenance, covering specific models and years. Downloading the correct manual is vital for DIY enthusiasts and professionals alike.

Common Electrical Issues in 2-Stroke Johnson Outboards

Common issues include ignition system malfunctions, faulty gauges, and wiring connections. These problems often stem from worn-out components or corrosion, requiring careful diagnosis and repair.

4.1 Ignition System Malfunctions

Ignition system malfunctions are common in 2-stroke Johnson outboards, often caused by faulty spark plugs, ignition coils, or wiring issues. These problems can lead to poor engine performance, misfires, or failure to start. Diagnosing such issues requires a multimeter and a wiring diagram to identify and repair damaged components effectively, ensuring reliable engine operation.

4.2 Faulty Gauges and Indicators

Faulty gauges and indicators in 2-stroke Johnson outboards can cause misleading readings or complete failures. Issues often stem from loose connections, corroded wires, or defective sensors. A wiring diagram is crucial for tracing circuits and identifying problematic components. Regular inspection and cleaning of electrical connections can prevent such malfunctions, ensuring accurate performance monitoring and reliable operation of the outboard motor.

Safety Precautions When Working with Electrical Systems

Always wear protective gear and ensure the system is de-energized before repairs. Avoid water contact to prevent shocks, and use multimeters safely to check live circuits.

5.1 Proper Use of Safety Gear

Always wear insulated gloves, safety glasses, and a fire-resistant apron when working with electrical systems. Ensure all gear is in good condition and properly rated for electrical work. Use a multimeter safely, avoiding direct contact with live wires. Disconnect the battery before starting repairs and verify the system is de-energized using a voltage tester. Consult the wiring diagram to understand potential hazards and protect yourself effectively.

5.2 Best Practices for Avoiding Electrical Shocks

Always disconnect the battery before starting repairs to eliminate power sources. Use a multimeter to verify no voltage is present. Avoid touching live wires or components with bare hands. Ground yourself by wearing anti-static straps or grounding tools. Consult the wiring diagram to identify live circuits. Ensure all connections are secure to prevent accidental shorts. Wear insulated gloves and goggles for added protection while working on electrical systems.

Online Resources for 2-Stroke Johnson Wiring Diagrams

Reliable websites offer downloadable PDF manuals, while forums and communities provide technical support and wiring diagrams for 2-stroke Johnson outboards, ensuring accurate repairs and maintenance.

6.1 Reliable Websites for Downloading PDF Manuals

Several websites, such as Seloc and marine-manuals.com, offer comprehensive PDF manuals for 2-stroke Johnson outboards. These resources include detailed wiring diagrams, service guides, and repair instructions. They cater to various models and years, ensuring enthusiasts and technicians can access accurate information. These platforms are trusted for their reliability and ease of navigation, providing essential support for DIY repairs and maintenance.

6.2 Forums and Communities for Technical Support

Online forums like Boat Forums and IBIninja offer valuable technical support for 2-stroke Johnson outboard wiring issues. These communities provide access to experienced technicians and enthusiasts who share insights, troubleshooting tips, and resources. Members often discuss wiring diagrams, common problems, and repair solutions, making these platforms indispensable for resolving complex electrical issues and maintaining outboard motors effectively.

Understanding Wire Color Coding in Johnson Outboards

Wire color coding in Johnson outboards is crucial for safety and repairs. Standard colors like red, black, and yellow denote specific functions, ensuring accurate electrical connections and troubleshooting.

7.1 Standard Color Codes for Electrical Wires

In Johnson outboards, standard wire color codes are crucial for safe and accurate repairs. Red typically denotes positive battery connections, while black signifies ground wires. Yellow often represents tachometer or ignition circuits. Secondary colors, such as white or blue, may indicate specific functions like trim or tilt controls. Adhering to these codes ensures proper electrical connections and minimizes risks of short circuits or system malfunctions during troubleshooting or maintenance.

7.2 Exceptions and Variations in Wiring Colors

While standard color codes are consistent, exceptions exist. Older Johnson models may use different colors for ignition or trim systems. For instance, yellow might indicate a tachometer in one model but a fuel gauge in another. Always consult the specific wiring diagram for your outboard to ensure accuracy, as variations can lead to incorrect connections if not properly identified and addressed during repairs.

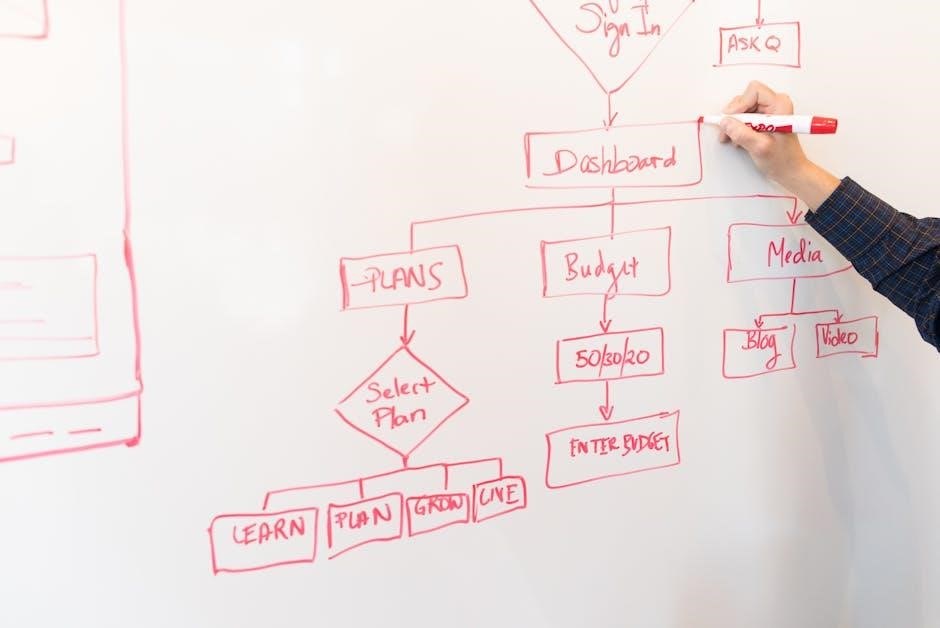

Step-by-Step Guide to Reading a Wiring Diagram

Start by identifying key components like the battery, ignition, and gauges. Trace circuits methodically, following colored wires and symbols to understand connections and power flow.

8.1 Identifying Key Components on the Diagram

Locate essential parts like the battery, ignition switch, and gauges. Color-coded wires and symbols represent components such as the trim motor, tilt mechanism, and ground connections. Each part is labeled, showing its role in the system. Understand the function of each component to diagnose and repair issues effectively. This step ensures a clear understanding of the wiring layout and connections.

8.2 Tracing Circuits and Connections

Begin by identifying the power source, typically the battery, and follow the live wires to components like the ignition switch and fuses. Use the wiring diagram to trace connections to the ignition coil, gauges, and trim/tilt motors. Verify each connection’s purpose, ensuring proper flow of electricity. This process helps pinpoint faults and ensures repairs are made accurately, avoiding potential electrical hazards.

Maintenance Tips for 2-Stroke Johnson Outboard Motors

Regularly inspect wiring and connections for corrosion or damage. Clean electrical components and apply protective coatings to prevent wear. Ensure all systems function properly.

9.1 Regular Inspection of Wiring and Connections

Regularly inspect wiring for signs of corrosion, wear, or damage. Check all connections and terminals for security and cleanliness. Use a multimeter to test voltage and continuity. Ensure battery links and electrical components are tightly secured. Apply protective coatings to prevent corrosion. Refer to your wiring diagram for accurate identification of circuits and connections during inspections.

9.2 Cleaning and Protecting Electrical Components

Regularly clean electrical components using a soft brush or compressed air to remove dirt and debris. Apply a marine-grade protective coating to shield wires and connections from corrosion. Avoid harsh chemicals that may damage insulation. Ensure all components are dry before reassembly. Use dielectric grease for terminal protection. Refer to your wiring diagram for specific cleaning and protection guidelines tailored to your outboard motor;

Advanced Troubleshooting Techniques

Use diagnostic tools like multimeters to identify complex electrical faults. Refer to wiring diagrams for circuit tracing. Seek professional assistance for issues beyond basic repairs to ensure reliability and safety.

10.1 Using Diagnostic Tools for Complex Issues

For complex electrical issues, use diagnostic tools like multimeters to measure voltage and resistance. Oscilloscopes can analyze ignition signals. Thermal cameras detect heat-related faults. Consult wiring diagrams to trace circuits and identify malfunctions. Advanced troubleshooting requires precise tools and a thorough understanding of the system. Always refer to repair manuals or online forums for additional guidance and solutions.

10.2 When to Seek Professional Assistance

If you encounter complex electrical issues or lack confidence in your troubleshooting skills, seek help from a certified marine technician. Persistent problems with ignition, gauges, or wiring may require specialized tools and expertise. Don’t risk safety or further damage; consult a professional to ensure proper repairs and maintain your outboard motor’s reliability and performance.

Always consult the wiring diagram for safe and effective repairs. Refer to online resources for additional guidance and keep the diagram handy for future maintenance and troubleshooting needs.

11.1 Importance of Following the Wiring Diagram

Adhering to the wiring diagram ensures accurate repairs and maintenance, preventing electrical failures and safety hazards. It provides clear guidance for identifying components and troubleshooting issues, making it indispensable for both novices and experienced technicians working with 2-stroke Johnson outboards.

11.2 Encouragement to Keep the Diagram Handy for Future Repairs

Keeping the wiring diagram easily accessible ensures quick reference during future repairs, saving time and reducing confusion. It serves as a valuable resource for maintaining your outboard motor’s performance and longevity, helping you address issues efficiently and confidently with clear visual guidance always available.